What is COMPASS?

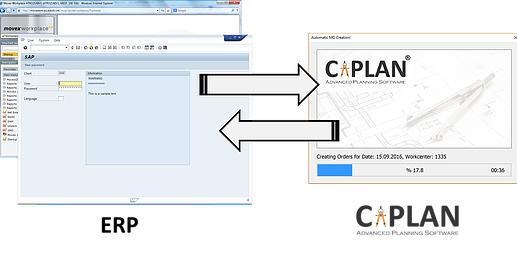

COMPASS is an advanced planning software running integrated to ERP systems.

COMPASS can work ONLINE with main ERP systems.

But also the connection can be OFFLINE, for a quick start, where installation will only few take days.

Why is COMPASS needed?

Because BAD planning costs you...

- Backlog to Customers

- Overtime Work

- Premium Freight

- High Inventory

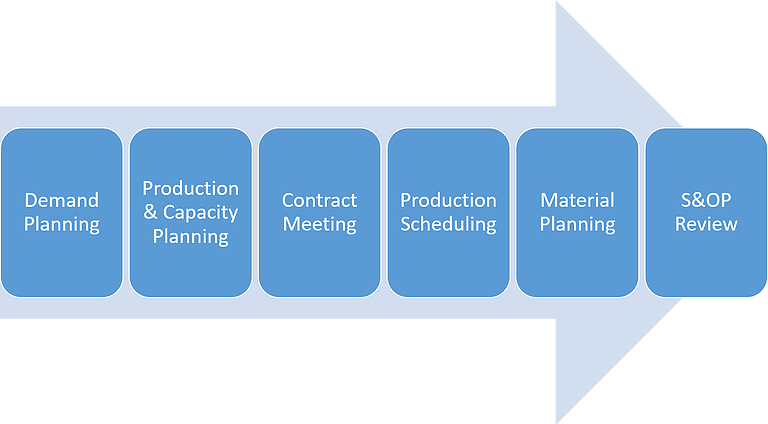

S&OP Process

Implement the automated S&OP process in your company, where you can plan longer periods of time ahead.

Do not stay in the dark, use COMPASS and easily forecast:

- Needed Manpower

- Needed Machine capacity

- Inventory Level

- Working Pattern

- etc.

Demand Planning (Customer Order Management)

Good Planning starts with accurate customer forecasts. Therefore, COMPASS has a state-of-the art Customer Order Management Module.

Start analyzing Customer Orders by comparing different versions sent by customer,

Fill in missing

parts in your forecast by

- analyzing past data ( e.g. seasonal changes), or

- transpolating future data (e.g. Nr. of products your customer plans to produce)

split

split & add

fine tune

add

When you are finished editing, you can save the edited version in COMPASS, so that you do not destroy the original version in ERP. This way, operation is always safe and changes are comparable as well as reversible.

Supply Planning (Capacity Management)

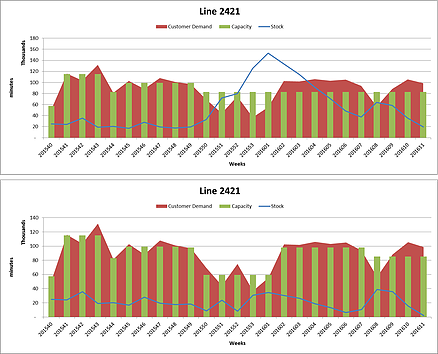

COMPASS will show Orders vs. Capacity in a few seconds.

You can quickly study various manufacturing strategies, and decide on the most cost affective solution for your organization.

Scenario 1

Scenario 2

You have products with different production rates on the line? No problem!

COMPASS can work based on MINUTES, so you compare apples with apples while analyzing the load on your line. Precise planning for accurate results...

You work on your strategy...

COMPASS works on details inline with your strategy...

Production Scheduling

Decided on the manufacturing strategy?

Now, it is time to decide which products will be produced on the line. Thanks to unique algorithm of COMPASS, the manufacturing load of the line can be translated to individual partnumbers automatically.

COMPASS automatically categorize the products as regulator parts & spare parts, and creates the production schedule accordingly.

Of course, the production schedule will not have more orders than line can produce.

Material Planning (Forecast to suppliers)

Finished with the production schedule, it is time to order the material.

Upload the production orders into the ERP system and MRP will run based on the production orders.

Never fear of missing material or excess stock, your material plan is connected to your manufacturing strategy...